The Best Wood to Build a Cordwood House

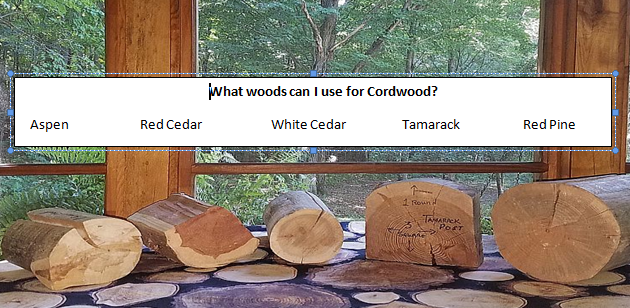

1 of the Oftentimes Asked Cordwood Questions (FACQ) is: "What type of wood can I use?" At one time, the answer was, "Annihilation you got." Just over time folks realized that at that place were good, better and all-time options for woods selection. To narrow down your choices let's place the forest on a continuum. Hardwoods are dense, and accept a tendency to swell and crack mortar joints; thus making softwoods the better option In that location are quite a few choices, but the all-time one is a naturally rot-resistant, disease-costless, disuse-resistant, insect-resistant softwood with a depression shrinkage rate and a loftier R-value.

With all that taken into consideration, cedar stands out as an ideal wood for cordwood. Are others that work? Admittedly. The pines piece of work very well, only they have a bit more shrinkage and are decumbent to insect infestation and the wood must exist peeled immediately and dunked in a borax solution.

Types of Wood for Cordwood

- Depression-density softwoods like Cedar and Pine work best. Their cellular construction has more airspace and provides better insulation and less shrinkage.

- High-density hardwoods like oak and maple are heavier and more compact and peachy when subjected to water/humidity.

- Cedar is rot-resistant, smells good, is lightweight and has a pleasing color.

- The following is a list of forest that tin be successfully used within a cordwood wall (pay attention to the volumetric shrinkage rate, which volition tell you how much your wood will shrink after cutting).

Volumetric shrinkage (total shrinkage) of cedar, pino, tamarack & aspen

- Northern White Cedar volumetric shrinkage seven.2%:Cedar is the platonic wood for cordwood because it possesses so many of the qualities needed to make a successful cordwood edifice. However, other forest can be used with confidence. Often the terminal result is in the proper grooming.

- Cerise Pino volumetric shrinkage 11.iii%

- Virginia Pine volumetric shrinkage 11.9%

4. Lodge Pole Pino volumetric shrinkage eleven.1%

v. Aspen volumetric shrinkage 11.5% rated as non-durableWith aspen (poplar) the face up of the log will often turn black from UV and rain. This is a skilful candidate for staining the exterior log face.

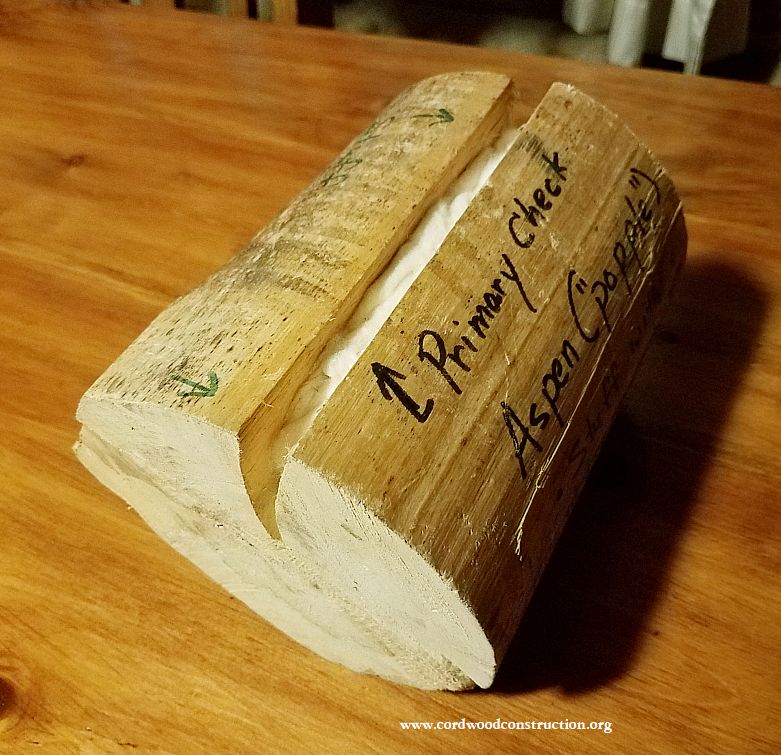

If yous get out the wood circular, it is going to develop a chief check. You can fix this (by stuffing) before or afterward the wall building.

6. Tamarack volumetric thirteen.6% moderately durable Tamarack is a very dense softwood and if not split and dried can have the same outcome as a hardwood (swelling, cracking mortar joints, pushing walls out of plumb). Tamarack is all-time used for posts, beams, and boards.

7. Red Cedar volumetric shrinkage vii.8% Aromatic, decay/insect resistant, durable, allergen

- Ane of the best sources of information on shrinkage, durability, rot resistance, etc. of diverse woods is at www.wood-database.com It is the all-time site I have constitute. The best wood(southward) for cordwood should exist the best rated y'all can detect for

- one. Shrinkage

- 2. Immovability

- 3. Rot Resistance.

- Go to the website http://world wide web.wood-database.com and use the search bar to type in the wood. In order to be considered Good for Cordwood, the Volumetric Shrinkage Rate should be well-nigh seven-8% (Cedar is just a picayune over 7.0%), the wood should have some rot & insect resistance and be listed equally durable. You lot can use wood that are not highly rated but you must 1. Split ii. Treat 3. Place them "up" off grade four. Use a damp proof membrane 5. Build large overhangs and gutter your roof.

Recent woods of interest to readers:

BLACK COTTONWOOD

Populus trichocarpa

Shrinkage:Volumetric: 12.four%

Rot Resistance:Rated as not-durable, and also susceptible to insect attack.

EASTERN Scarlet CEDAR

Common names: Aromatic Red Cedar, Eastern Redcedar

Juniperus virginiana

Volumetric shrinkage: 7.8%

Rot Resistance: Regarded as excellent in resistance to both decay and insect assail, Aromatic Carmine Cedar is frequently used for fence posts used in direct basis contact with no pre-treating of the wood.

WESTERN RED CEDAR

Mutual names: Western Redcedar, Western Red Cedar

Thuja plicata

ShrinkageVolumetric: half dozen.8%

Western Crimson cedar has been rated as durable to very durable in regard to decay resistance, though it has a mixed resistance to insect assail.

As you tin see, the cedars excel in every category.

If y'all are going to employ forest other than cedar, you lot will want to decide whether you have to care for the wood with borax (a not-toxic, naturally occurring production) to stop or forestall insect harm. A solution is made of hot water and borax (1 gallon of hot water to four cups of borax, mix thoroughly and dunk the log ends for 30 seconds each. Allow dry out.

Shrinkage information from the Wood Database http://www.wood-database.com/ These are while cedar round logs in a cordwood wall. Each has adult a principal check. The cheque runs all the way through from the outside to the inside. This lets air flow into the house. In this movie, the check is being stuffed with white fiberglass to match the mortar colour. You can apply brown paper numberless, newspaper, caulk (information technology has to be a moveable caulk or it will CRACK) or any type of fabric that looks decent. The cheque needs to be filled on the outside and the inside.

These are while cedar round logs in a cordwood wall. Each has adult a principal check. The cheque runs all the way through from the outside to the inside. This lets air flow into the house. In this movie, the check is being stuffed with white fiberglass to match the mortar colour. You can apply brown paper numberless, newspaper, caulk (information technology has to be a moveable caulk or it will CRACK) or any type of fabric that looks decent. The cheque needs to be filled on the outside and the inside.

When a wall has mostly all splits and they are well dried, there is usually very footling log loosening, air infiltration or primary checking.

When a wall has mostly all splits and they are well dried, there is usually very footling log loosening, air infiltration or primary checking.

Information technology is of import to cheque the moisture of your wood using a wet meter. These are hands obtained online.

HOW TO DRY YOUR Wood: The first dominion of air drying wood for cordwood is to get it in the Lord's day. In a single row, covered on pinnacle. If yous can orient information technology north and due south to take advantage of the sun as information technology goes from east to west (or as my science friends would say the earth is really doing that motion ). Then make sure it is covered on the tippy peak. If you want to speed upwards the drying, split 70% of the wood. Divide wood dries faster. If yous can claw upwardly a powerful fan to accident on the rows of wood–moving the fan daily-y'all can help dry out the wood even more (this is a proffer from the Wood Handbook put out by the USDA). A borax/borate dunk is likewise a expert way to rid the forest of mildew, fungus, and bugs. Borax is a wood preservative, a fungicide, an insect repellant, and a burn down retardant.  Mix 4 cups of Borax (like xx Mule Squad Borax Laundry Detergent) with a gallon of hot/hot/hot water and dunk the log ends into the saucepan/tank for a minute or two. And then stack them to dry.

Mix 4 cups of Borax (like xx Mule Squad Borax Laundry Detergent) with a gallon of hot/hot/hot water and dunk the log ends into the saucepan/tank for a minute or two. And then stack them to dry.  The bottom line is you are working to get the wood to its Equilibrium Moisture Content (that's 12% in the upper Midwest, 7% in the desert). You can find the right % by asking at your local lumber yard or wait at the EMC table in the book Cordwood Construction All-time Practices on folio 66. You should too get a moisture meter to check the sides and the end to make sure it is dry enough to mortar into your wall. If it is not dry out enough it volition shrink in the wall and create air infiltration gaps.

The bottom line is you are working to get the wood to its Equilibrium Moisture Content (that's 12% in the upper Midwest, 7% in the desert). You can find the right % by asking at your local lumber yard or wait at the EMC table in the book Cordwood Construction All-time Practices on folio 66. You should too get a moisture meter to check the sides and the end to make sure it is dry enough to mortar into your wall. If it is not dry out enough it volition shrink in the wall and create air infiltration gaps.

I style to keep the round "look" and non accept the principal check or log loosening problem is to "explode" the circular logs (separate them) and so put them back together in the wall.

AVOID THIS RESULT. (Below) This is oftentimes the result when your woods is not dried to its lowest Equilibrium Wet Content. The logs can be punched out of the wall.

In the photo above all the rounds accept shrunk. Avoid this by splitting 70% of your wood and drying to 12% wet content.

This is what nosotros are trying to avoid. A log that was not dry out enough, developed a big main check and loosened severely in the wall. How to avoid this? Use softwood, dry it well, split most of information technology and use a slow setting, slow curing mortar as I propose in my book Cordwood Structure Best Practices.

This is what mortar groovy looks like. What causes this? The mortar mix is too rich in Portland cement, it needs more sawdust to make information technology weaker (weaker being a skilful thing in terms of wood masonry). It was also mortared in the hot sun, which dried information technology out too fast. It was not covered subsequently the workday to slow downward the set and cure.

If you don't utilise a "Best Practices" arroyo, your cordwood walls can be drafty and crave significant maintenance to seal them properly.

Should you wish to learn how to build a cordwood cottage, cabin or home, please visit www.cordwoodconstruction.org While you are there, click on the pictures, read the brief articles, check out the latest workshops and newsletter and if yous are interested click on the ONLINE BOOKSTORE to see all the cordwood literature available in impress and ebook format. If you take questions that aren't answered on the website you can electronic mail me at richardflatau@gmail.com

If you take questions that aren't answered on the website you can electronic mail me at richardflatau@gmail.com

Readers take requested a cursory bio, then here goes:

Richard & Becky Flatau built their mortgage-free cordwood home in 1979 in Merrill, Wisconsin. Since then, they have written books, conducted workshops, facilitated the 2005, 2011 and 2022 Cordwood Conferences and provided consultation for cordwood builders. Cordwood Workshop DVD (2018), Cordwood Construction Best Practices (print 2017) and Cordwood Conference Papers 2015 are the newest publications available from their Online Cordwood Bookstore. The books & DVD are also available as ebooks for a quick and easy shipping free download.www.cordwoodconstruction.org

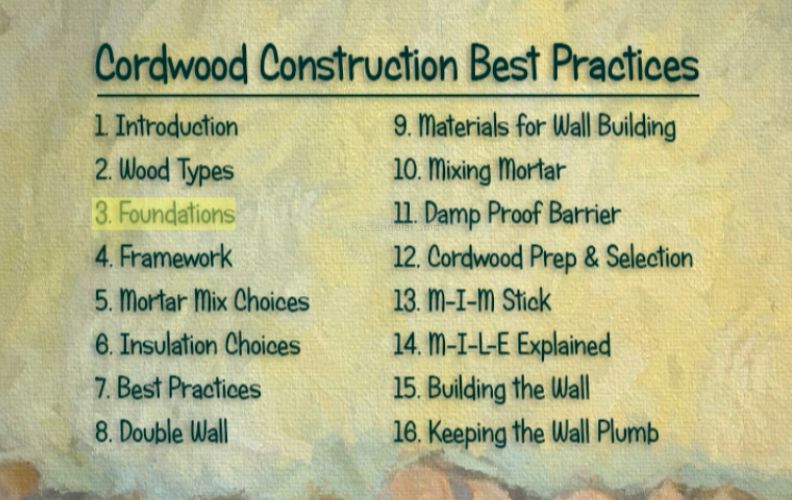

This is the Cordwood Workshop DVD will show you lot how to build aAll-time Practices cordwood domicile.

The 30 detailed menu items from the Cordwood Workshop DVD.

Thank y'all for your kind attention to Cordwood Structure. If y'all would similar more than information, please visit world wide web.cordwoodconstruction.org

Thank y'all for your kind attention to Cordwood Structure. If y'all would similar more than information, please visit world wide web.cordwoodconstruction.org

Or emailrichardflatau@gmail.com

Source: https://cordwoodconstruction.org/best-wood-for-cordwood

0 Response to "The Best Wood to Build a Cordwood House"

Postar um comentário